Tel : +86-577-62665555

+86-577-62668988

Business Email : Jacky.dxm@qq.com

KYN28-24 Metal enclosed middle-mounted switchgear

Published in2018-08-03

Published in2018-08-03 8577 Views

8577 ViewsDetailed description

Product description

In order to meet the requirement for wall mounting and front-end maintenance, the switchgear is equipped with a special current transformer, so that the operator can maintain and inspect it in front of the cubicle.

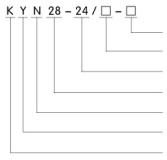

Model explanantion

Rated breaking short circuit (KA)

Rated breaking short circuit (KA)

Rated current (A)

Rated voltage (KV)

DesIgn Serial Number

Indoor

metal clad

switchgear

Applied standards

| No. | Standard no. | Title |

| 1 | IEC 62271-200:2003 | AC. Metal-enclosed switchgear and controlgear for rated voltage above 1kV and up to and including 52kV |

| 2 | IEC 62271-1:2007 | High-voltage switchgear and controlgear - Part 1: Common specifications |

| 3 | IEC 60060-1:2010 | High-voltage test techniques - Part 1: General definitions and test requirements |

| 4 | GB 3906-2006 | Alternating-current metal-enclosed switchgear and controlgear for rated voltage above 3.6kV and up to and including 40.5kV |

| 5 | GB/T 11022-2011 | Common specifications for high-voltage switchgear and controlgear standards |

| 6 | DL/T 404-2007 | Alternating-current metal-enclosed switchgear and controlgear for rated voltage above 3.6kV and up to and including 40.5kV |

| 7 | GB 50060-2008 | Code for design of high voltage electrical installation (3 ~ 110kV) |

| 8 | GB/T 16927.1-2011 | High-voltage test techniques - Part 1: General definitions and test requirements |

Operation conditions

◆ Normal and special use conditions

Ambient temperature: the highest temperature is +40℃. The minimum temperature is -15℃, and the average value measured in 24h is not more than 35℃.

The humidity conditions are as follows:

——The average relative humidity of the day is not more than 95%, and the mean monthly relative humidity is not more than 90%.

——The average daily vapor pressure does not exceed 2.2 kPa, the average monthly vapor pressure does not exceed 18 kPa.

Condensation occurs occasionally under such conditions.

Altitude not exceeding 1000M

The ambient air is not significantly polluted by dust, smoke, corrosive and/or combustible gases, vapors or salt sprays.

Vibration or ground motion outside the switchgear and control equipment is negligible.

The amplitude of electromagnetic interference induced in the two system does not exceed 1.6K.

◆ Special conditions of use

The company and the user can negotiate and reach an agreement on special operating conditions when they are used under normal environmental conditions beyond the stipulations of GB/T11022.

To prevent condensation, the switchgear is equipped with a heater, which should be put into use when the switchgear is in a standby state. When switching devices are running normally, they should also pay attention to the heater.

Technical parameters

◆ Main technical parameters of switchgear

No

Item

Unit

Parameter

1

Rated

voltage

KV

24

2

Rated

frequency

Hz

50

/ 60

3

Rated

insulation level

1Min.

frequency tolerance

KV

Interphases

65

Isolated

fracture

79

Lightning

impulse tolerance voltage

125

145

Auxiliary

control voltage

V

2000

4

Rated

current

A

630,

1250, 1600, 2000, 2500, 3150

5

Rated

short circuit breaking current

KA

6

Rated

short circuit closing current (Peak)

KA

7

Rated

short time withstand current 4s

KA

8

Rated

peak endurance current

KA

9

Auxiliary

control circuit rated voltage

V

10

Protective

level

IP4X (Doors of

compartments are open, the degree is up to IP2X)

11

Outline

dimensions (W x D x P)

mm

800x1800x2300; 1000x1800x2300

12

Total

weight

Kg

750

~ 1440

Structure and working principle

◆ Structure description

KYN28-24 switchgear is made up of two parts: the cabinet body and movable part (commonly known as handcart). The cabinet is divided into several functional compartments with metal partitions, such as bus bar room, circuit breaker room, cable room and relay instrument room.

The movable parts of switchgear can be configured with vacuum circuit breaker handcart, voltage transformer handcart, lightning arrester handcart, isolation handcart and flame breaker handcart.

Switching equipment can be arranged back to back or installed against the wall, which not only improves the safety and flexibility of switching equipment, but also reduces the floor area.

◆ Enclosure

The shell of switchgear is made of imported aluminium-zinc coated steel plate, processed by CNC machine tool and made by multiple folding process. The whole cabinet has high precision and strong anti-corrosion and anti-oxidation performance, and because of the use of multiple folding process, the cabinet than other similar equipment cabinet overall light weight, high mechanical strength, beautiful appearance. The cabinet is assembled with pull rivet nuts and high strength bolts, which shortens the processing and production cycle, has strong versatility of parts and components, occupies less space, and is easy to organize production.

◆ Handcart

The handcart skeleton is made of thin steel plate after being processed by CNC machine tool. The handcart has high accuracy with the cabinet, and the mechanical interlock is safe, reliable and flexible. Handcarts are divided into circuit breaker handcarts, voltage transformer handcarts, metering handcarts, isolation handcarts and so on according to their different uses. Handcarts of the same specifications can be freely interchanged. The handcart has disconnection / test position and working position in the cabinet, and there are positioning devices in each location. To ensure reliable interlocking. All kinds of hand cars are driven and withdrawn by silk bar. The operation is light and flexible, and is suitable for duty personnel operation. When the handcart needs to be removed from the cabinet, a special transporter can be used to remove it for various inspections and maintenance.

When the handcart is transported into the cabinet circuit breaker room, it can be reliably locked in the open/test position, and the cabinet position indicator shows its position. Only after the handcart is fully locked can the screw drive mechanism be moved and the hand cart is pushed to the working position. When the handcart reaches the working position, the operating force of the propulsion handle increases suddenly and does not move, and the corresponding position indicator lights show its position. The mechanical interlocking of the handcart can reliably ensure that the handcart can be closed only at the working or testing position, and the handcart can move only when the circuit breaker is in the braking state.

◆ Septum

The main electrical components of switchgear are in its separate compartment, namely: circuit breaker handcart room, bus room, cable room, relay instrument room, etc. The protection level of each compartment is IP2X. Except for the outside of the relay meter, there are pressure relief passageways in the other three compartments. Due to the adoption of the middle form, the space of the cabling room is greatly increased, so the equipment can connect multiple cables.

a) busbar compartment A:

Double bus bar is adopted. For special requirements, busbars can be covered by heat shrinkable tubes and custom insulated covers. Insulation pipes are installed between buses of adjacent cabinets. If the internal barrier arc occurs, the bushing can effectively limit the accident to the compartment without extending to other cabinets.

b)Circuit Breaker Room B: Tracks are installed on both sides of the compartment for the handcart to move from the disconnection/test position to the working position in the cabinet. The partition (valve) of the static contact box is installed on the back wall of the handcart chamber. When the handcart moves from the disconnection/test position to the working position, the upper and lower valves on the static contact box opens automatically with the handcart; when the valve moves backward, the valve closes automatically until the handcart has retreated to a certain position and the static contact box is securely covered, thus forming an effective static contact box. Isolation. Because the upper and lower valves are not linked, the valves on the charged side can be locked during overhaul to ensure that the maintenance personnel do not touch the charged body. When the circuit breaker door is closed, the handcart can also be operated. Through the observation window on the door, the position of the handcart in the compartment, the indication of closing and braking and the state of energy storage can be observed.

c) switchgear adopts the middle position, so the space of the cable chamber is large. The current transformer and grounding switch are installed on the back wall of the compartment (the grounding switch can also be installed in the middle of the switch cabinet according to customer's needs), and the lightning arrester is installed at the back and bottom of the compartment. After the handcart and the extractable horizontal partition are removed, the constructors can enter the cabinet and install them from the front. Cable connection conductor in cables room, each phase can be connected with 1-3 cables, if necessary, each phase can be connected with 6 cables, cabinet compartment cabinet bottom preparation can be unloaded slotted metal seals or magnetic conductivity metal seals to ensure convenient construction.

d) Mountain Relay Instrument Room D: The relay instrument room can be equipped with relay protection elements, instruments, live indicator and special requirements of the second equipment. The number of control lines is set online, and the line has metal plates, which can isolate the two line from high voltage components. The left front line phase is reserved for the introduction and extraction of the control system. The secondary line and the electric piercing hole are arranged at the corresponding part of the floor. On the empty roof of the relay instrument, a small busbar body for easy work is left over the hole, and the cover plate of the instrument room can be opened when wiring, so as to facilitate the installation of the small busbar.

◆ Pressure relief device

Pressure relief devices are installed above the handcart room, bus bar room and cable room. When arcing occurs in the compartment, the pressure inside the switchgear rises. The special sealing ring installed on the front door closes the door of the cabinet. The pressure relief metal plate of the top device is opened automatically to release pressure and high temperature gas, thus ensuring the operators and switchgear. Safety of preparation

◆ Position interlock of two plug and handcart

The secondary connection between switchgear and handcart is realized through the connection of the secondary plug, which is connected with the handcart through a nylon corrugated expansion tube, and the secondary socket is installed on the upper right of the handcart in the switchgear. The handcart can only be inserted or removed two times when it is in the test / disconnection position. When the handcart enters the working position, the two plug is locked. The circuit breaker handcart equipped with closing and locking electromagnet can only be opened and can not be closed before the second plug is connected.

◆ Live display device

The switchgear can be equipped with a live display device for detecting the operation of the primary circuit. The device consists of a high-voltage sensor and a display. The device can indicate the live state of the high voltage circuit, and cooperate with the electromagnetic lock to realize the forced locking of the operation handle, the cabinet door and the adjacent cabinet, so as to prevent the moving and isolating handcart with load, prevent the live closing of the earth switch, and prevent the incorrect entering of the live interval.

◆ Prevent condensation

In order to prevent condensation in high humidity or temperature environment, electric heaters are installed in circuit breaker room and cable room respectively to prevent insulation accidents under the above operating conditions.

◆ Grounding device

The cabinet is separately equipped with a 5 *40mm grounding copper bar, which runs through the adjacent cabinets and is well connected with the cabinet body for the use of directly grounded components. As the whole cabinet is joined together with aluminum-zinc coated sheets, the whole cabinet is in a good grounding state, ensuring the safety of operators when touching the cabinet.

Other Similar Products